Vacuum Belt Filter Cloths

Experience uncompromising quality for reliable and efficient filtration solutions. We specialize in providing filter cloth products tailored to the specific needs of each client. We deliver uncompromising quality to provide reliable and efficient filtration solutions.

We deliver worldwide

Quote within 24 hours

Exceptional performance

Our collaboration with Septek Filter over the years has resulted in optimal filter cloth products for dewatering our products, with both long lifespan and high filtering capacity.

Mikael Selin, Imerys

Our filter cloths for horizontal vacuum belt filters come in a variety of different specifications. By choosing the right cloth together with different options of edge treatments and seam connections we aim to find the most efficient secure filter belt installation for your application.

Design features

We use various design features depending on the requirements, including:

- Edge treatments

- Seam connections

Filter cloth fabrics

Different fabrics in double layer weave are used depending on the application, including:

- Polypropylene

- Polyester

Yarn designs

Our range of yarn designs include:

- Multifilament yarns

- Monofilament yarns

Benefits

Our vacuum belt filter cloths provide the following benefits:

- High filtration capacity

- Good cake washing

- Good cake discharge

- Flexibility of filter cloth

Over 40 years of experience in the filtration

As a supplier and manufacturer of filter press cloths with over 40 years of experience in the filtration industry and extensive collaboration with clients across various industries, we have refined our approach to helping clients achieve optimal filtration performance. Our approach is built upon the following pillars:

- High-quality products. There is a significant performance difference between a high- and low-quality filter press cloth. Striving for the highest quality is therefore our main priority. With every product we make, our goal is to find the best solution to enable more cycles, drier filter cakes, improved cake release, and clearer filtrate, saving clients time and money.

- Unmatched service level. We work closely with our clients to deliver the best possible solution specifically tailored to their application to enable exceptional performance.

- Short lead times. Our clients trust our ability to deliver industry-leading lead times, reducing frictions in their process.

- Innovation. We embrace a forward-thinking approach, constantly striving to deliver cutting-edge solutions that push the boundaries of performance.

All you need to know about our Vacuum Belt Filter Cloths

A vacuum belt filter cloth is a specialized filtration fabric used in Horizontal Belt Vacuum Filters (HBVF) to separate solids from liquids in various industrial applications. It provides mechanical stability and efficient drainage while handling fine filtration.

Vacuum belt filter cloths are commonly made from polypropylene and polyester, which offer durability, chemical resistance, and mechanical stability. These materials are woven into double-layer or multi-layer weaves to enhance filtration efficiency.

Mostly double-layer and multi-layer weaves, as well as needle felt fabrics, are used to create a mechanically stable and durable belt filter cloth. These materials enhance both drainage and filtration efficiency. A combination of different yarns and weave types is utilized to optimize performance for specific applications.

HBVFs are widely used in mineral processing, gypsum production, catalyst recovery, and pharmaceutical manufacturing, where medium-to-low resistance cake applications require efficient dewatering.

The choice of filter cloth directly affects cake formation, dewatering speed, and filtrate clarity. A properly selected cloth ensures minimal blinding, optimal cake release, and extended service life.

Key factors include:

- Slurry characteristics (particle size, pH, temperature, chemical composition)

- Filtration rate and cake formation

- Mechanical strength and durability requirements

- Resistance to chemical and thermal degradation

Replacement frequency depends on the operating conditions, slurry composition, and maintenance practices. Signs of wear include reduced filtration efficiency, fabric blinding, and mechanical damage.

- Regular cleaning to prevent clogging and blinding

- Proper tensioning to avoid excessive wear

Using suitable washing systems (high-pressure water or chemical cleaning) - Monitoring operating conditions to prevent unnecessary stress on the fabric

- Ensuring rollers are straight and free from sticky slurry material to maintain proper cloth alignment

Yes. Multi-layer weaves and specialized fabric structures are designed to handle fine filtration while maintaining good drainage and cake release properties.

- Polypropylene (PP): Offers high chemical resistance, low moisture absorption, and good mechanical stability.

- Polyester (PE): Provides better temperature resistance and is ideal for applications with elevated operating temperatures.

Air permeability should be chosen based on the desired filtration rate, cake thickness, and vacuum pressure. Too high permeability may lead to poor cake formation, while too low permeability can slow filtration.

- Regular backwashing or high-pressure cleaning

- Periodic chemical cleaning for oily or sticky slurries

- Optimizing slurry conditioning with flocculants or coagulants

Yes, filter cloths can be tailored by adjusting weave type, material selection, air permeability, and edge reinforcement to match the specific needs of a filtration process.

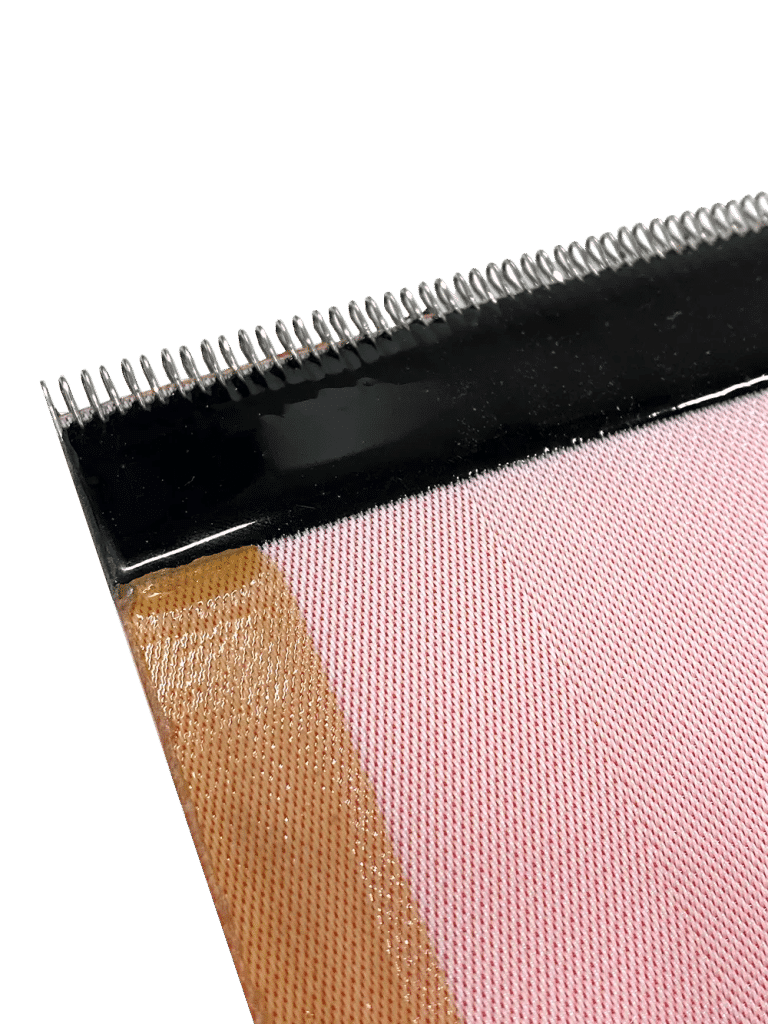

Vacuum belt filter cloths can be supplied with different connection methods and edge treatments to enhance durability and ease of installation:

- Connection types:

Clipper seams for easy installation and replacement.

Welded solutions for improved strength and sealing. - Edge treatments:

Ultrasonic sealing to prevent fraying and improve longevity.

Polyurethane-treated edges for added durability and resistance to wear.

- Increased filtrate turbidity (reduced clarity)

- Uneven cake formation or poor cake release

- Frequent clogging or fabric blinding

- Physical damage (tears, fraying, or excessive stretching)

- Wrinkles in the cloth, which can indicate improper tensioning or fabric degradation and may lead to inefficient filtration.

- Uneven cloth length on both sides, which can cause misalignment and operational inefficiencies.

- Ensure proper alignment and tensioning to prevent wrinkles or misalignment.

- Both sides of the cloth should be perfectly even in length to ensure smooth operation.

- Check for leaks or improper sealing after installation.

- Rollers should be straight and clean from sticky slurry material to maintain proper cloth movement.

- Run a trial cycle to confirm proper operation before full production.

A trusted partner commited to delivering excellence

We take pride in the fact that our products have earned the trust and confidence of numerous leading companies across a diverse range of industries. From renowned mining and minerals companies to reputable players in the paper and pulp sector, as well as those involved in chemical processing and beyond, our solutions have consistently delivered exceptional results.

With our extensive track record and expertise, we have become a trusted partner for businesses seeking reliable and high-performance products. We understand the unique challenges and demands faced by different industries, and our commitment to delivering excellence has earned us a reputation for consistently surpassing expectations. Contact us today to learn more about how our tailored solutions can address your specific application needs.